December 1, 2023, was the first post on this site when it was reimagined, and it has been a very busy two years. I started and completed my second master’s, applied and was accepted into a doctoral program, considered withdrawing from the doctoral program, applied for and was accepted into a third master’s program at Johns Hopkins, before deciding to recind my application to that program, and now, waiting for the start of the Spring term to re-engage with the doctoral program already underway. This reengagement was only possible after taking the fall term off to seriously reevaluate whether or not I would continue with this doctorate. In all honesty, the majority of the ‘drama’ has been between last July and September. However, it is official, I am enrolled in the spring term for my last academic class, HIUS 713 American Entrepreneurship Since 1900, and my first dissertation class, HIST 901 Doctoral History Research. I still have three Comprehensive Examination and Reading classes, HIUS 911 Early America, HIUS 912 Modern America, and HIEU 914 Modern Europe, before starting the formal dissertation phase, when I can consider myself a Doctoral Candidate and not just a Doctoral Student.

I have a wide range of interests, which has been both a blessing and a curse. On the positive side, it is relatively easy to shift from one subject to another and to learn new methods for presenting research. It also allows for a broader perspective to view subjects of research. This is great as a student in the academic setting, less so outside the academe. In a time where increasing specialization is the preferred mode, being a generalist can be disadvantageous. On the negative side, falling down a new rabbit hole is all too easy. It can be difficult at times to set the blinders and focus on one thing. This has been a contributing factor in not having fixed on a specific topic for the upcoming dissertation.

As a maker, my perspective on history is often guided by how things were done. Understanding how things were done and how the processes of doing have evolved can open up many avenues of inquiry in the historical record. At the core of making, for me at least, is knowing how things function and how they were made. Thus, my broad interests in machinery, transportation, communications, engineering, architecture, and design. Woodworking is one of the root trades for all of these categories. From Archimedes’ water screw to wind and water mills, wagons & carts, the printing press, early long-distance mechanical visual communications systems, and of course, the shelter and furnishings of our ancestors for thousands of years. Woodworking is also a self-supporting craft with tool-making historically being a key skill learned by the apprentice early on, making their own tools, chests, and benches, all being made in whole or in part from wood.

Before moving north from the San Francisco Bay Area to the Klamath Basin, a fair amount of time was spent building a workshop space that focused on bookbinding, restoring old tools, and woodworking.

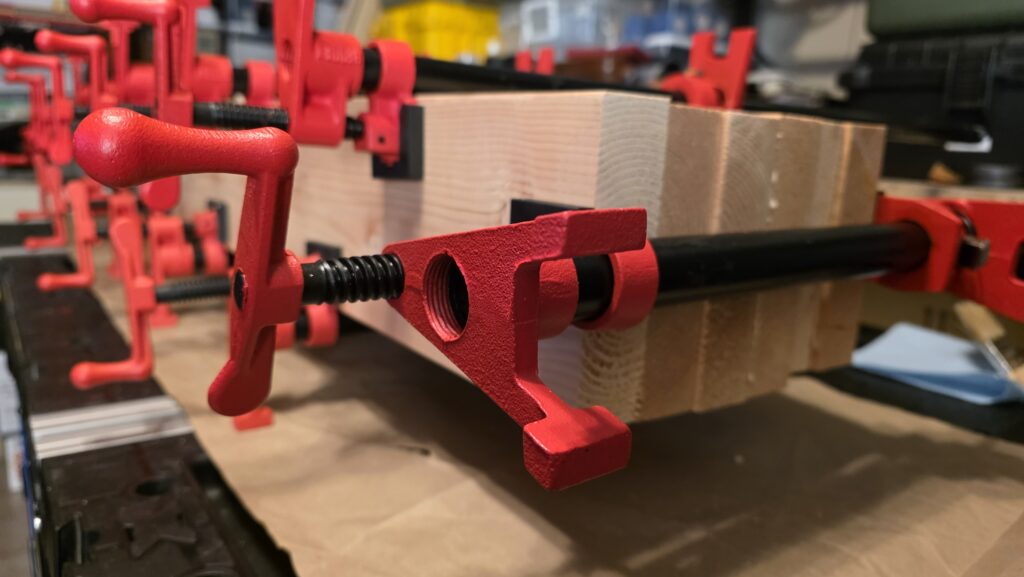

One thing that did not make the move was the workbench. Proper positive workholding is one of the most important keys to effective and safe workshop processes in wood, metal, plastic, or any material. Without a proper workbench since moving, many cherished shop skills have languished in disuse. This week marks a reversal, a new heavy bench is now under construction.

The new bench is an interpretation of the traditional hand tool joiner’s bench. The list of projects that will rely on this bench includes the cabinetry and chests that will replace all of the current shop furniture, making specialized hand tools, making workholding & pressing tools for book repair and binding, and furniture making. Most of these projects will also have a historical component to them, particularly the tool and furniture projects.

One of the concepts under consideration for a dissertation includes developing and employing a framework for Experimental History, using period-appropriate tools and methods to replicate an object of importance to a specific line of research inquiry, whether as an artifact or process. If this concept is to be included in the upcoming dissertation, there will most certainly be a need for tool and pattern making, as well as the construction of the object of inquiry itself. This requires the re-establishment of a working shop, the joiner’s bench being the anchor of the shop.

Between shop projects and the possibility of employing Experimental History, the urgency of getting a working hand tool shop up and running is high. To that end, the materials for the bench were acclimating in the shop last week: (10) 2″ x 8″ x 10′ nominal fir construction lumber, and a 6/4 – 14″ x 12′ maple slab. Two days ago, the materials were milled down from nominal lumber to near-dimensional boards, and yesterday, glue-ups started for the major components in rough sizes: (4) legs 5″ x 4″ x 36″, (4) stretchers 5″ x 3″ x 48″, and (1) bench top 5″ x 20″ x 60″. By the end of next week, all of the glue-ups should be done, and final dimensioning can begin. The target size for the bench is a 5″ thick bench top, 20″ deep, 60″ wide, standing 32″ tall, with a 1″ thick fir shelf about 7″ from the floor, inset into the stretchers. The draw-bore mortise and tenon joinery should be all marked out and cut next weekend over the winter solstice. Installation of the mapleface, back, and ends, along with a Moxon-style face vise, tail wagon-vise, the hold-fast and dog holes, and finishing should be done over Christmas week. The plan is to be finished and dressed by January 1st, so work can begin with the new year.